Product Description:

The Thermal Spray Powders product is a high-quality powder used for coating applications in various industries. This product is specifically designed to provide excellent performance and durability in harsh environments.

Color: Dark-gray Powder

Apparent Density: 2.9 – 5.8 G/cm3

Coating Thickness: 20-500 Microns

Porosity: 1-5%

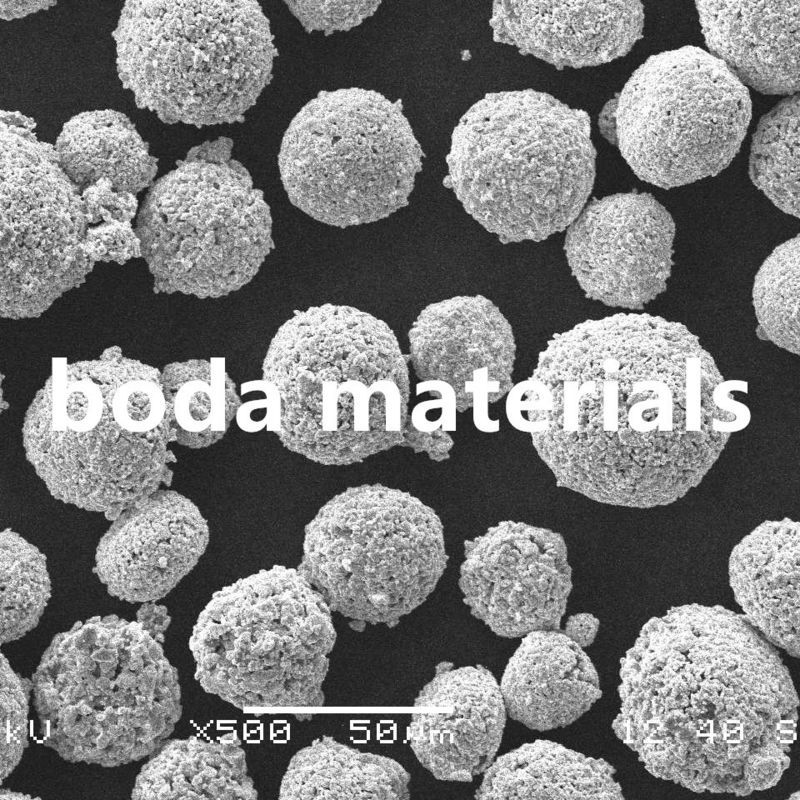

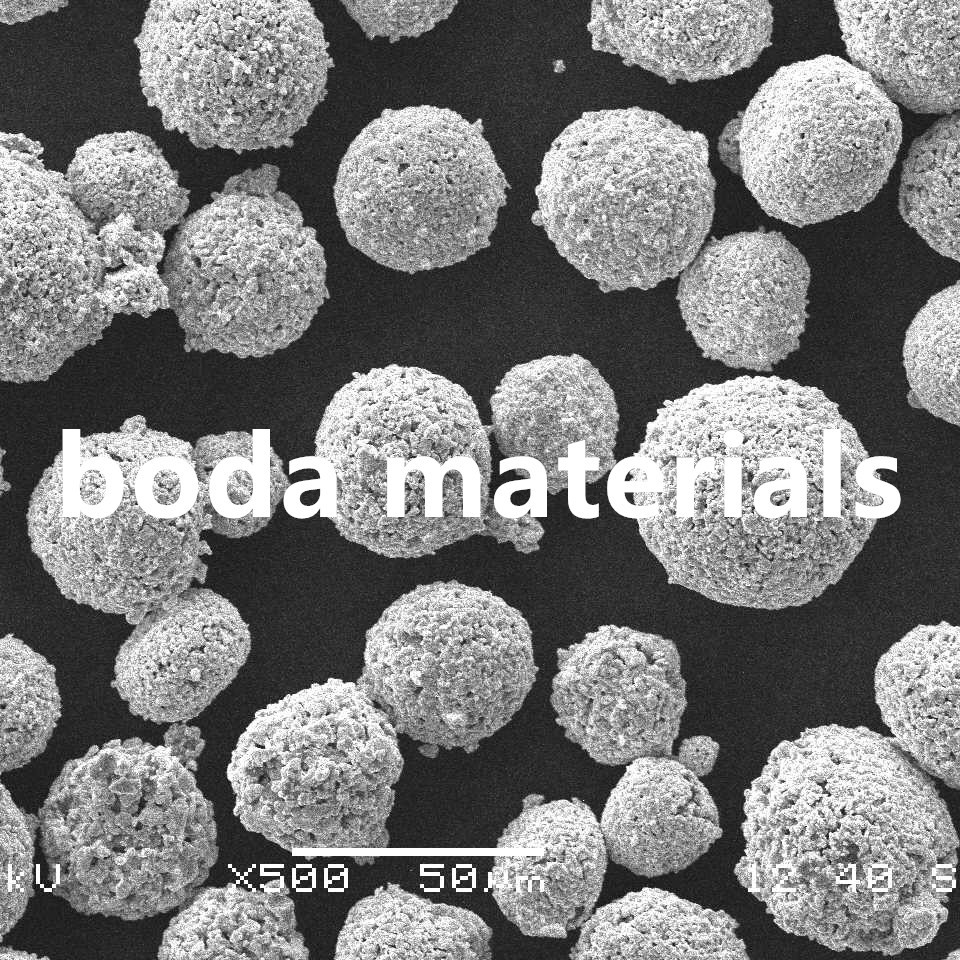

Morphology: Angular / Blocky

One of the key features of this product is its composition, which includes HVAF WC-CO-CR. This composition ensures superior hardness, wear resistance, and overall performance of the coating.

The Thermal Spray Powder WC-10Co-4Cr is a versatile product that can be used in a wide range of applications. It is known for its ability to create highly durable coatings that can withstand extreme conditions.

Whether you are looking to enhance the lifespan of industrial components or improve the performance of engineering parts, the WC-CO-CR Thermal Spray Powder is an excellent choice. Its unique properties make it suitable for use in aerospace, automotive, and other demanding industries.

With an apparent density ranging from 2.9 to 5.8 G/cm3, this powder ensures optimal coverage and adhesion when applied as a coating. The coating thickness can be adjusted from 20 to 500 microns, allowing for customization based on specific requirements.

Additionally, the porosity level of 1-5% ensures that the coating maintains proper ventilation and thermal insulation properties. This is essential for preventing corrosion and other forms of degradation in the coated surfaces.

The angular and blocky morphology of the powder particles further enhances the bonding strength and overall performance of the coating. This unique shape allows for better interlocking of particles, resulting in a more stable and resistant coating.

Overall, the Thermal Spray Powders product offers a reliable solution for protecting and enhancing the surfaces of various components. Its HVAF WC-CO-CR composition, combined with the specified attributes, makes it a top choice for industries seeking high-performance coatings.

Features:

-

Product Name: Thermal Spray Powders (Thermal Spray Powder WC-10Co-4Cr, HVAF WC-CO-CR, WC-CO-CR)

-

Corrosion Resistance: Excellent

-

Hardness: 500-2000 HV

-

Shape: Irregular

-

Chemicals: Ni 17.5-22% C 7.5-10% Cr Balanced

-

Porosity: 1-5%

Technical Parameters:

|

Coating Thickness

|

20-500 Microns

|

|

Porosity

|

1-5%

|

|

Morphology

|

Angular / Blocky

|

|

Typical Hardness

|

1400-1700 HV0.1

|

|

Chemical Composition

|

Metallic Or Ceramic

|

|

Spray Process

|

Flame, Plasma, HVOF

|

|

Apparent Density

|

2.9 – 5.8 G/cm3

|

|

Corrosive Wear Resistance

|

Corrosive Wear Resistance

|

|

Hardness

|

500-2000 HV

|

|

Chemistry

|

WC 12Ni

|

Applications:

BODA Thermal Spray Powders, Model Fine Size WC-10Co-4Cr, are versatile products that find application in various industries and scenarios due to their exceptional quality and performance attributes.

Product Application Occasions and Scenarios:

-

Aerospace Industry:

The HVAF WC-CO-CR powders are ideal for coating components in the aerospace sector to enhance their durability and resistance to wear and corrosion.

-

Automotive Sector:

These thermal spray powders are well-suited for applications in the automotive industry where components require high hardness and corrosion resistance, such as engine parts and exhaust systems.

-

Oil and Gas Field:

The corrosion-resistant properties of the WC-10Co-4Cr powders make them a preferred choice for coating equipment used in the oil and gas sector, protecting against harsh environmental conditions.

-

Mechanical Engineering:

With a coating thickness ranging from 20-500 microns, these powders are suitable for use in mechanical engineering applications where wear resistance and surface protection are crucial.

-

Industrial Manufacturing:

The BODA thermal spray powders are widely used in various industrial manufacturing processes to improve the longevity and performance of machinery and equipment.

These powders are ISO9001:2015 certified, ensuring high quality and reliability. The minimum order quantity is 50kgs, with a price range of $60-65/kgs. Each order comes in 50kgs drums, and delivery typically takes 7-10 days. Payment terms are negotiable, and the supply ability is 10 tons per month.

With a chemical composition of Ni 17.5-22%, C 7.5-10%, and Cr balanced, these powders offer excellent corrosion resistance. The typical hardness of 1400-1700 HV0.1 makes them suitable for a wide range of coating applications. Their irregular shape allows for uniform and efficient coating deposition.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!